1972 Porsche 914

Disassembly - Part 10 - Windshield Area

9/22/2006

Removal of the Front Targa Seal

Ok, it's time to tackle the windshield seal. This is the one that

runs along the top and down the sides. Along the top it acts as a

seal between the Targa top and the windshield frame. Along the

sides, between the frame and the doors. The issue here is that this

part is no longer available from Porsche. There is at least one

reproduction that is available, but I believe there are supply and quality

issues with that seal. NOS seals go for quite a bit on eBay.

So if you need to remove your seal (as I do), you want to try to not tear

it up.

Ok, before we go much further I have to admit that I did break the seal

into two pieces (passenger side) during the removal process. However, I do

feel that after figuring out how to do this, now would be able to remove

it without breaking or tearing it. I was able to get the driver side OK

after I learned how to do it on the passenger side. Hopefully these

instructions will help you successfully remove yours without destroying

it.

Ok, now to get down to business, first I didn't realize that there are

actually two seals around the windshield. There is a lower seal that

removes pretty easily. It only runs the length of the top of the

windshield frame. The upper seal runs both the length of the top as well

as down both side of the windshield frame.

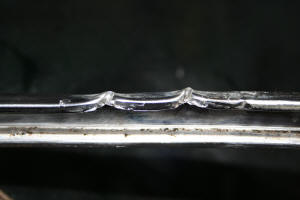

Hard to see in this photo, but there are two different seals here.

Here you can see me removing the lower seal. It only runs along

the bottom of the top part of the main Targa seal.

Note the profile. It sort of slips up under (I believe) the bottom part

of the upper seal. It is easy to remove.

Before I started, I had no real idea on how the upper seal was shaped and

attached to the body. The upper seal looks to have an embedded metal part

that both reinforces the seal as well as acts as a clamp. It connects to

the windshield frame in a tongue and groove fashion. The seal (and metal

clamp) act as the groove and the windshield frame as the tongue. As far as

I can tell, there are no adhesives used to attach the seal to the car

(either on the top or side)

I started out by experimenting and found that I could insert a thin

screwdriver between the seal and the frame along the top. I suspect that a

thin putty knife would work better, but my screwdriver was working well

for me, so I kept at it. By doing this, I was able to increase the gap. Do

this slowly and a little at a time. You may also want to just use your

hand periodically and wiggle the seal top and down a bit to help break it

free from the frame.

Screw driver going in at this point. I was nervous as I had no

idea how it was put together at this point.

But it did seem to be working.

And I was able to pull it away from the frame a bit.

I also tried to insert my finger and pull the lower part of the seal as

well. The idea here is to pull the seal straight out, but do it by

applying the pressure from the inside out vs. trying to just pull directly

on the exterior of the seal. Go slow, take your time, don't force anything

if you are doing it right, you should hear the seal clamp loosen and break

away from the frame section by section.

Eventually you will get a section to separate totally from the frame. One

this happens, you should be able to work the rest of the top away from the

frame pretty easily. Work you way right up to the intersection between the

top and side parts of the seal on each side.

At this point you need to remove the upright trim on the inside of the

windshield frame. On my 1972 model, there were three plastic caps that hid

three #2 Phillips screws. There is also a small #1 Philips screw right at

the intersection of the top and side parts of the seal. The small #1 is

easy to miss. A PO for my car had tried to solve a leak I this area by

applying some rubber sealant. The screws were buried under all of this.

Once this is done, you should be able to see both the inside and outside

part of the aluminum C shaped channel that holds this part of the seal.

Ok, now for the hard part. You will have two issues here. First, the seal

may not want to budge due to general friction and the fact that it has to

slide through a tight curve near the top. The other (which I think is the

real reason it is hard to remove this seal) is that when the seal is

installed at the factory, the C channel is "staked" on the inside in a few

places to prevent the seal from sliding after it has been installed.

These photos where taken AFTER this was all done, but it shows you what

the "stakes" in the channel look like. Mine have already been bent

out so that the seal would slide out.

You will need to pull back the seal with your fingers enough to inspect

the entire length of it on the interior side of the seal and find where it

has been staked. I had three stakes on one side (spread out along the

length) and two on the other (both near the end of the seal). So I assume

they can be anywhere and have a indeterminate number of them. You will

need to undo the staking enough so that the seal will be able to slide

along the C channel. I don't have any photos of this part, but I took a

wide blade screw driver and inserted it into the channel and dug and pried

enough to allow the seal to slide. You may really have to dig in there to

get enough of a bite to undo the staking. While my seal is of average

shape, the inside part of this seemed to be the most flexible and sturdy

part of the entire seal and I was able to really dig around at the channel

without damaging the seal. I suspect this is because this part of the seal

is typically hidden away from damaging UV light, etc. by the interior

trim.

I don't know how cheap or easily available a replacement is for this

aluminum channel. If it is cheap, I would not worry about what you do to

it to get it to the point that the seal will freely slide. I haven't tried

it yet, but I suspect that if you don't mangle it much, that you can bend

it back and reused it. The part you bend should be hidden by the trim once

reinstalled.

To help get the seal to slide, you will to lubricate it. I used a child's

medicine syringe (available at a pharmacy or grocery store) and soapy

water. I used regular glycerin dish soap and just a small bit of water.

Whatever lubricant you use, it should be water based and not petroleum

based (such as mineral oil).

You should see if you can wiggle the seal a bit in and out

(perpendicular to the channel) to see if you can loosen it up a bit

where it might be stuck to the channel. Then you can try to use the

syringe to squirt the soapy water in. If you get it in just the right

place up near the top, you should be able to get a stream to run the

entire length of the seal and drain out the bottom. Keep at it until you

feel you have the soapy water between the seal and the channel along the

entire length. It should run freely once it is loosed up.

After you have it lubricated, you may need to wiggle the intersection

area between the top and side a bit to break it free from the frame as

well. Be very careful as this is a very fragile area on the entire seal.

At this point, you can start to try to slide the seal. There are a

few key things to remember at this point...

- Do not whatsoever try to pull the seal by grabbing a hold of the

area around the intersection of the top and side piece. These pieces

have been extruded and/or molded separately and then connected during

the manufacturing process. They are weak where they have been joined

together.

- Start pushing from the bottom, but then work your way up along the

entire length by applying pressure on the seal in the direction that you

want it to move. Wiggle as you go and apply additional lubrication as

needed. Keep repeating this motion and if all is good, it should start

to move.

- If it is not sliding something is wrong. Check to make sure you have

undone the "staking" enough and that you can wiggle the seal along its

length. If it is lubricated enough and has broken free, you should hear

and see the soapy water squish out of the channel all along its length.

I started on my passenger side first. With much effort, I was able to

get the seal to start to move. I should have realized that

something was wrong as I was REALLY having to push hard from the bottom

and was tempted to pull from the top.

I then made the mistake of trying to

pull from the top. I was trying to not apply much pressure, but I ended

up causing the seal to separate at the joint. Don't do what I did.

It was a tough way to learn that lesson. DON'T PULL ON THAT JOINT.

At this point I felt I was pushing harder than I should need. I

realized that I had not undone the "staking" enough, so I fixed that and

added more lubricant. The seal then slid out much easier and without any

pulling needed to get it to move. Once I was able to get about three

inches of the seal out of the top, I felt I was able to safely pull a bit

from the top as well as push from the bottom to speed up the process.

Bottom line, if it doesn't slide out, then something is wrong.

Don't force it.

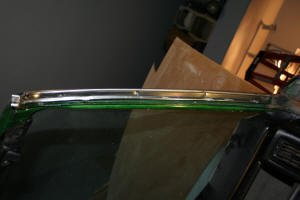

The aluminum channel is held in with a few #1 Phillips screws. I removed

mine and here are some of the stakes in the channel.

After I realized that my impatience was the reason I broke the seal and

that once the staking had been properly undone and the channel lubricated

it slid out without having to pull at the top, I decided to take it a bit

easier on the driver side of the seal. With the experience of the

passenger side, I was able to repeat the process on the driver side, but

without breaking the seal on this side. If I was to do it all over again,

I am positive that I could have remove the seal without breaking it.

The keys are to go slow, take your time and don't force anything.

Here are some misc. other photos...

![]()